Our New 32-bit Sorter Interface

We're Going RADical

No, we aren't shipping bombs with our programs. RAD stands for Rapid Application Development, a new way of writing Windows based programs. What once required writing hundreds of lines of program code now can be done in a few seconds by using the mouse. Using RAD we can now create custom Windows programs for a cost that is affordable.

There are several RAD programming systems available for use. Perhaps the most popular is Microsoft Visual Basic. Unfortunately, it uses older interpretive technology which runs slower than true native Intel instructions. It also doesn't provide full access to all the features of Windows. This forces the programmer to make compromises or purchase add-on packages to provide extra functionality.

We write our DOS based sorter applications using Borland Turbo Pascal. We chose this language back in 1984 because it compiled quickly, was bug free and could be used to easily build robust applications. During the years, Borland has kept Turbo Pascal current by adding object oriented features to make it easier to use modern mouse based interfaces.

In the last two years, Borland added RAD features to the language and renamed it Delphi. Using Delphi, it is easy to quickly produce modern 32-bit Windows 95 and NT programs. The new 32-bit Windows programs almost never crash and leave Windows in an unstable state. During the writing of this program we created several nasty bugs that would have locked up DOS or Windows 3.1. In Windows 95 we were able to continue working. An error message popped up on the screen and we needed to restart the program, but Windows 95 never stopped running.

Program Features

Modern 32-bit Interface

The system is programmed using the mouse and keyboard. Windows makes programming your sorts a breeze. The on-line help system provides information on every command and screen.

WIN32 Interface Breaks Memory Limit

In Windows 95 & NT there are few memory limits. Instead of working with many blocks of memory, each limited to a maximum of 65536 bytes, we can now use blocks hundreds of times larger. We can load huge data structures into memory and they are automatically stored to free space on the hard disk. Programs run faster because they don't need to access data through pointers.

Large Database Systems Possible

With all memory available, large scale mainframe tally data and ticket systems are realized. Tally and production files are sent to the mill's network server, giving all departments access to current data. Files easily import into spreadsheet and database programs.

Flexible System

We design our programs to provide flexible operation. The standard program accepts custom titles and tally factors. It is easily converted to metric sorting. The board sorting logic is optimized for modern product trends.

Extensive Diagnostics

Diagnostics go far beyond simple status displays. A real-time board queue shows each board on every j-bar. Errors and rejects are logged over the entire shift. That one time glitch is easily found.

Client-Server Network Connections

The protected mode DOS real-time multi-tasking sorter control program operates as a server on the network. The Windows 95 interface program provides client access to the sorter control program. The entire sorter database can be sent from the DOS program to the Windows interface in about 2 seconds. The remote Windows program always has up-to-date information.

Hot Backup

A backup computer can be easily added. The network is used to send sorting status data to the backup's hard disk. Should the main computer fail, the backup has a snapshot of the sorter that is at most 1-2 minutes old. Transfer cables from the main computer to the backup and continue sorting.

Speedy Planer Line Switching

The Sort Switch screens automatically move products in and out of the sorter. Only a few mouse clicks will instantly switch from one length to another. Tallies are optimized for quick processing. It takes about 5 seconds to capture a tally in the Windows program. It can then be processed into database format while the DOS computer runs more lumber.

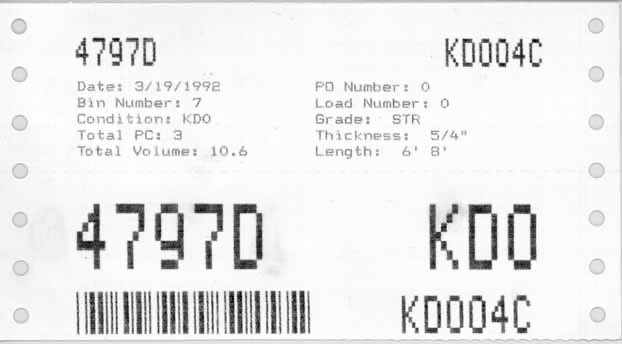

Inventory Control with Bar Code Tickets

Bar coded tickets allow easier yard inventory operations. A hand scanner can quickly enter the yard inventory in a few hours. Mt. Hood Software provides a wide range of ticket options.

Dot Matrix Printers: only provide printed information on the package contents. Bar code printing with these printers is not recommended. The mill usually buys preprinted tickets with their logo.

Bar Code Printers: print high quality text, graphics and bar codes. Printer and supplies are considerably higher in price than dot matrix printers. Can print scanned logos and other graphics.

Windows Printers: a standard laser printer can be used to print sheets of high quality output. Bar codes can be mixed with text and graphics to produce custom tickets. You can use standard Avery® self-adhesive labels or custom coated paper that will stand up to the elements. Laser printers are the only printers that produce output that won't run or fade when exposed to the elements. Laser printers use toner, a colored plastic powder, which is heated and bonded to the paper. We can supply you with samples to run through your process for evaluation. This is perhaps the best solution for package tickets and doesn't lock you into one printer or paper supplier.

Ticket Computer: a separate computer to collect and print the tickets. The computer is used to manually enter hand sorted items if necessary. Two ticket printers can be operated from the ticket computer for zero downtime when the ink or toner runs out.

Input & Output Options

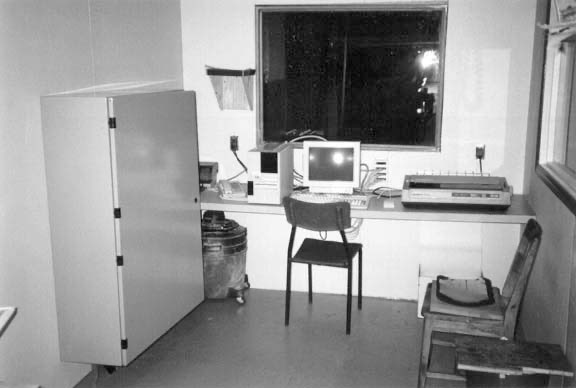

Small Footprint

The system fits in very small areas. A small interface panel is mounted near the computer to communicate with the control hardware. A typical office desk will hold the computer and printer. A higher cost industrial computer can be rack mounted in the mill environment if desired.

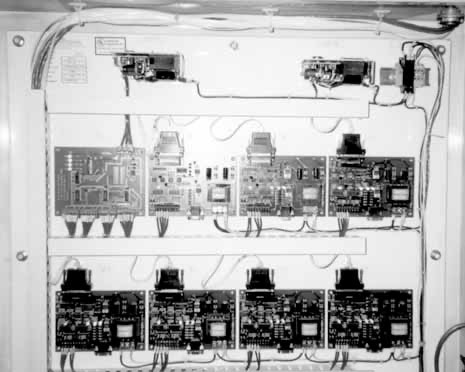

A typical installation with control interface rack.

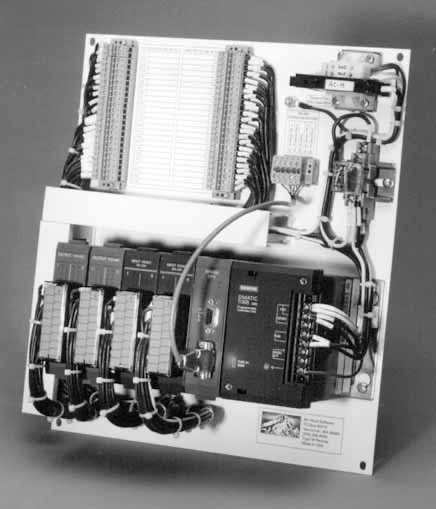

Remote I/O Interface Panel

A local panel interfaces to existing NAC or WGBM remotes, or new remotes. All hardware is custom built by a UL listed electrical contractor to assure quality and low cost. High voltage connections are optically isolated, at the interface panel and remote, to assure complete protection of the computer. Other remote I/O options include Allen-Bradley racks, Opto-22 relays and Siemens TI-305 racks.

A NAC remote interface panel installed into the existing NAC computer rack.

NAC & WGBM Remote Replacement

Mt. Hood Software also makes direct drop-in replacements for the NAC & WGBM remotes. A Siemens TI-305 PLC rack is combined with a Facts Engineering interface card and our custom software to create a completely compatible remote. Simply drop into the existing rack and connect field wiring. Replace only the computer and continue using the existing remotes for lower installation costs.

This is a TI-305 based WGBM remote replacement.

Reports and Database Features

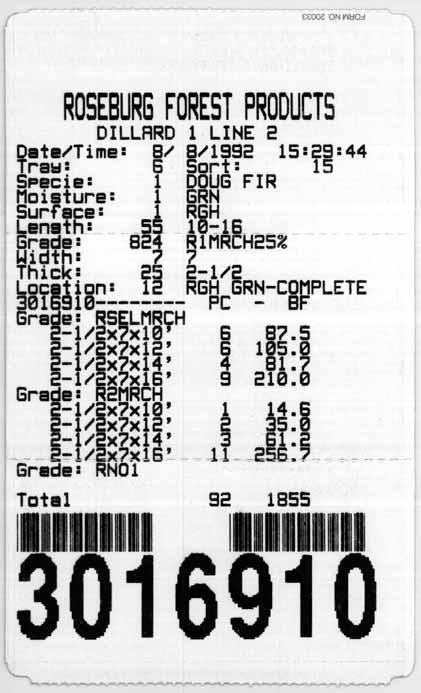

Tally System

A tally can be captured from the DOS sorter server at any time and only stops production for about 5 seconds. The tally is saved on the Windows computer's hard disk. The tally is then printed and processed into database files.

The tally is downloaded over the network in 5 seconds.

Accumulative Tallies

Tallies can be quickly added together to produce accumulative reports over periods of weeks or a month. You can quickly click and chose which tallies to add together on the screen.

Database System

The ticket information is saved in database files. These files are easily imported into any spreadsheet or database program. They track information on each board sorted into packages for a full accounting of production.

Inventory Control

Because the information is in standard Windows database files, you can implement your own inventory controls if desired. We can also provide you with a custom inventory system suited to your needs. Our experience with network system design allows us to provide you with a total mill solution.

Interface Features

Tally Reports

Tally reports can be viewed on the screen or printed. The options dialog allows you to set the font size, left print margin, grid lines and reduce to fit. Grid lines make it easy to match numbers across the report. Reduce to fit automatically adjusts the font size to fit the report onto the paper width.

Options dialog for setting program operation.

The sorter interface operates similar to standard spreadsheet programs.

Cut and Paste

The program operates similar to other spreadsheets. You can easily select a block of numbers or text, cut it to the Windows clipboard and then paste it into another application such as Excel.

Tools and Menus

We use standard Windows menus, tool bars and a tabbed spreadsheet interface to make using the program easy. Everything is laid out in a logical format for ease of use when programming sorts.

Program is off-line and ready to download a new sorting matrix.

On or Off Line Mode

To make it easy to setup new sorting patterns to run, the program operates in an off-line mode and stores the data in files on the disk. Once you have dumped the bins and taken the tally, you can download the file to the DOS machine for the next run.

The program is on-line and showing package sorts. A bar at lower left shows network activity.

PLC Based Sorter Controls

We also supply Allen-Bradley PLC-5 based sorter controls. The PLC sorter has all the same features as the PC based sorter controller, the only difference is hardware cost. An Ethernet interface for a personal computer costs $50. The same interface on a PLC-5 processor costs $1,500. A PLC-5/40 by itself, without Ethernet, costs about $9,300 list. A Pentium computer only costs $2,000 to $2,500 and can run the sorter all by itself. If you are willing to pay an extra $7,000 to allow your electricians to modify the program, go with the PLC (and that doesn't include extra software costs or spares). We leave the choice to you.

Our PLC-5 system installed in an old NAC computer enclosure.

Excel Spreadsheet Interface

This specific PLC-5 system uses a custom Excel Visual Basic interface requested by the customer. We can provide Excel if you want it. By the time the data flows out of Excel, into the Windows DDE system, through Wintelligent LINX, onto the network and into the PLC, it can take up to a minute to download a new sort program into the PLC. The amount of data downloaded into the PLC is only about 1/4 of the amount downloaded into the PC program in 5 seconds. Try running LINX on the PLC serial channel and you can really go slow. If you really want this industry standard interface, we will gladly provide it.

An example of the Excel interface.

Delphi Custom Interface

If you want to work fast, use our custom Delphi based program. Forget the DDE system, throw away Wintelligent LINX (save $1000) and run just as fast. The PC will talk to the PLC using the RS-232 serial channel and save the cost of the PLC Ethernet interface too ($900). The performance will be almost equal to the more expensive LINX-Ethernet interface. Our PLC network server running on the local computer will allow other clients on the network to control the PLC just like the PC server.